|

| October 04, 2016 | Volume 12 Issue 37 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Engineer's Toolbox:

PEM fasteners a key to curved-keyboard success

PianoArc (Boston, MA) has struck a resonant chord in the world of music by pioneering incredibly clever circular and curved keyboards for performers at live concerts and stadium events around the globe. The unique keyboard designs and layouts have changed the way that artists approach their music and serve as fresh evidence that creativity and innovation are alive and well up and down the scale.

One of the assembly challenges for PianoArc designers from the outset was how keyboard units could be attached securely to compatible stands. For this critical function, PEM self-clinching nuts from PennEngineering (Danboro, PA) became the keys to success.

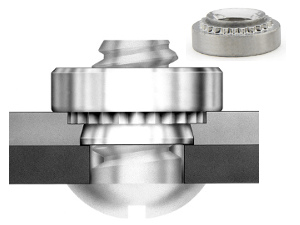

PEM basic self-clinching nuts.

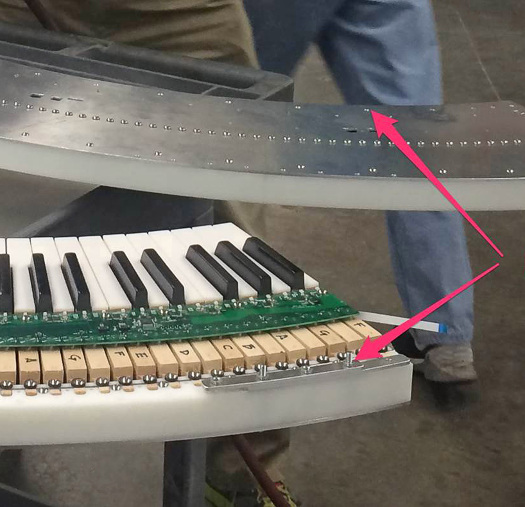

Almost 32 PEM carbon steel self-clinching nuts play roles in each of PianoArc's two most popular keyboard offerings: the circular Brock360 and the semi-circular DualWing designs. The nuts specified for both of these applications install permanently in 1/8-in.-thick machined aluminum panels that compose the keyboard stands -- creating load-bearing threads in the very thin sheets and providing high pushout and torque-out resistances. Mating screws complete attachment of units to stands.

Pushout values indicate the axial resistance of a fastener to remove it from the sheet opposite to the direction from which it was installed, and should be roughly 5 to 10 percent of the force used to install the fastener. Torque-out resistance is the amount of torque necessary to spin the fastener out of the sheet. This is torque applied to the fastener. No axial load is applied.

PEM fasteners installed for attaching keyboard units.

"For years we have trusted PEM hardware," says Dave Starkey, chief technical officer at PianoArc and the originator of the company's mechanical and electronic keyboard designs. "PEM fasteners simply work." Upon their installation (in these applications they are manually pressed into place using an arbor press instead of automatically), the fasteners ultimately remain intact, never loosen or fall out, and will not jeopardize unit integrity or performance on the road or in concert.

"Reliable attachment of keyboard units and stands is obviously essential," Starkey adds, "and the PEM nuts consistently do the job without fail."

All the PianoArc keyboards are wonders to behold and to hear. The Brock360 -- a circular controller keyboard style with a 6-ft outer diameter -- launched as the world's first circular keyboard controller and features sprung (unweighted) CNC-machined keys and 288 contiguous notes. The semi-circular DualWing (which debuted in 2016) is engineered as dual 72-note controller keyboards equipped with synth action, a carbon-fiber top, integrated (midi-programmable) light show, and custom mounts for control surface, laptop, and microphone mounts.

Sound from the keyboards is generated from MIDI/USB outputs, and any MIDI or software sound solution can be employed. As for playing such a radically re-configured instrument, Starkey reports that for many performers, it can be relatively easier than tickling the ivories on conventional pianos.

"The key dimensions where the white/black keys intersect are the same as a traditional piano," Starkey says, "and it seems to translate easily to most keyboard techniques. The curvature actually places the natural key intervals closer together, enabling 10th intervals for many of those with a normal octave reach."

As would likely be expected, the question most asked by performers: "How do I find middle C?"

"The latest designs include LEDs that indicate the section/channel division," according to Starkey. "By default, there are three middle Cs in the Brock360 -- and it is even possible to configure up to 24."

For almost 75 years, PEM self-clinching fasteners have been writing fastener history as hardware solutions for attachment applications across industries. The PEM nut was the very first PennEngineering product introduced when the company was founded in 1942. Since then, the lineup of PEM brand self-clinching fasteners has expanded to the tune of dozens of different types (in addition to nuts) in thousands of styles and variations. Compared with alternative attachment options, self-clinching fasteners often will hit more of the right notes than other methods can reach.

For example, if disassembly will be required to allow for service or repairs, designers will quickly rule out welding, adhesives, and high bond tapes, largely because they represent "permanent" joining methods. And alternative hardware, such as sheet-metal screws, can cause their own issues over time. These include diminishing holding power, reduced thread integrity, and likely loosening and falling out. As for tapping, extruding, or stamping threads into a metal sheet, sheets will often be too thin and the task too impractical. In addition, poor-quality threads can be expected from such operations.

"The choice of PEM hardware does away with all the usual drawbacks associated with conventional joining technologies," says Starkey. "Self-clinching fasteners and thin metal sheets were made for each other."

The benefits of all self-clinching fasteners effectively arise from their design incorporating an annular recess (for permanently locking the fastener in place in a thin ductile metal sheet) and an element to prevent fastener rotation in service.

Regardless of type, self-clinching fasteners install permanently by pressing them into place in a properly sized hole and, when sufficient squeezing force is applied using a press, the fastener's serrated clinching ring, knurl, ribs, or hex head is forced into the panel surface, displacing sheet material into a specially designed annular recess in the shank or pilot of the fastener, known as an undercut. The metal forced into the undercut secures the fastener against axial movement, while a non-round displacer secures the fastener against rotation.

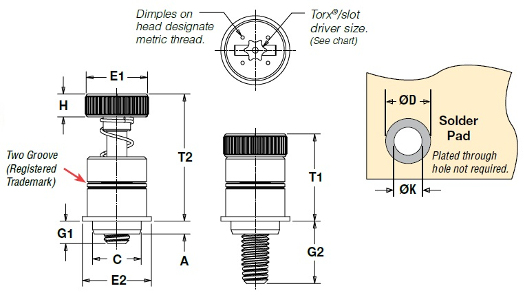

PEM ReelFast Type SMTPFLSM surface-mount spring-loaded captive panel screws.

"No secondary operations are necessary, which has quickened our production pace," Starkey says. In addition, the PEM fasteners inherently reduce the number of loose parts (such as washers, lock washers, and nuts) that would have to be inventoried and handled.

According to Starkey, the longtime experience with PEM hardware has contributed to a potentially new application now in the works at PianoArc.

"We're considering mounting a force sensor resistor module to our units," Starkey explains. At least eight modules are planned for each piano to be installed at a printed circuit board assembly house.

Instead of self-clinching fasteners -- solely purposed for thin metal assemblies -- PianoArc is looking to set the stage with PEM ReelFast Type SMTPFLSM surface-mount spring-loaded captive panel screws. These install where designed on printed circuit boards (the boards for PianoArc are .062-in. thick) to provide secure attachment and allow for subsequent access.

PEM Type SMTPFLSM-2.

The all-metal captive screw assemblies mount in one piece on boards using the pick-and-place method and will install in the same manner and at the same time as other surface-mount components prior to the automated reflow solder process. They are supplied on tape and reel conforming to industry standards and are compatible with existing SMT automated installation equipment.

"The captive panel screws will allow us to quick-mount the modules as customer options," Starkey adds.

Over the years, PianoArc keyboardists, designers, and technicians have rocked the music scene as a team by blending music and technology to present instrument creations that wow performers and audiences alike -- with PEM brand hardware accompanying in harmony all along the way.

For more information:

- Visit PennEngineering at www.pemnet.com, email at info@pemnet.com, or call +1-800-237-4736 (toll-free in the USA) or +1-215-766-8853.

- Visit PianoArc at www.pianoarc.com, email at please-reply@pianoarc.com, or call +1-978-344-2883.

Source: PennEngineering

Published October 2016

Rate this article

View our terms of use and privacy policy